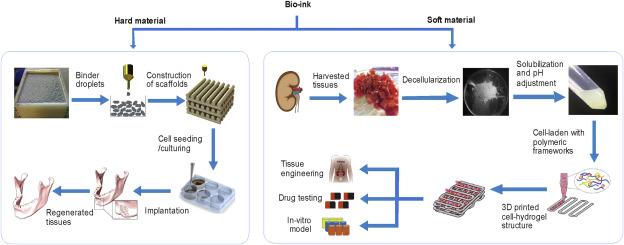

3D bioprinting is considered as a means to advance and accelerate the development of the field of tissue regenerative medicine. The forming principle of general biological 3D printing is very simple:

Is similar to the principle of FDM, the printing material instead of hard plastic wire but a liquid, or melted, or thick, or gel fused cells (material) flow from material cartridge (out), and through the control of mechanical system of three-axis extrusion head is piped out print on the tray, forming an object is obtained by physical or chemical effect in curing, so as to create a 3 d entity.

In short, bioprinters differ from mainstream 3D printers in that, instead of using layers of plastic, they use layers of biomaterials or cell building blocks to create actual living tissue.

According to the application field, it can be roughly divided into the following categories :

Bone regeneration

Hydroxyapatite polyhexalactone

Tricalcium phosphate levolactic acid

Polylactic acid - glycolic acid copolymer

Drug controlled release

Poly has lactone

L-polylactic acid

Polylactic acid - glycolic acid copolymer

Soft tissue, cell and organ printing

Agar lecithin alginate chitosan

Gelatin hyaluronic acid fibrin collagen

Applications and Prospects

Organ transplantation can save the lives of many patients whose organs have failed or damaged, but the technique also has drawbacks such as insufficient organ supply and inevitable rejection. However, with the advent of biological 3D printers, there are new technical means to solve these problems. What we are able to do today for the time being is print soft tissue, skin. Such tissue can be used for drug research, where researchers can test problems with new drugs in the early stages and evaluate their efficacy, and the process allows us to produce more practical models, in contrast to how 2D cell cultures cannot be used in a suitable 3D environment.

The use of bioprinting speeds up clinical trials to verify the efficacy of new drugs and reduces the number of animal trial failures. In the beauty field, where the goal is to eliminate animal testing altogether, many companies are currently working on skin tissue models. A lot of work has been published by great scientists in materials science, neuroimaging, toxicology, and so on. In clinical studies, patient CT and MRI scan data is used to generate STL files to print solid 3D models that can be used as templates for implants.

In the future, the development direction of biological 3D printing is to develop from non-special equipment and special equipment to high-throughput integrated special equipment. Material research direction from non-biocompatible materials, biocompatible materials, biodegradable biocompatible materials to print special biomaterials direction.

This is the current stage, we usually called the mainstream biological 3D printer principle and application direction. You might be wondering what a bio-3D printer looks like. What's different from our usual 3D printer? Don't worry. We will introduce the mainstream biological 3D printer series from all over the world. Today I would like to introduce Inkredible +, a cost-effective "desktop class" bio-3D printer from Sweden.

Inkredible + Biological 3D Printor is a pneumatic extruded biological printer equipped with two print heads and a UV-curing system for printing complex human tissues and organs for tissue engineering research. For innovators who want to enter the field of bio-3D printing, this is an easy to use and cost-effective bio-printer that can be monitored by using the accompanying software on the computer.

Here are some basic parameters of Inkredible + Bio-printer:

Inkredible + Bio-printer advantages

Doubles print head

Double-print heads allow you to use different types of cells in the same component without switching cartridges or pausing the printing process. This makes it possible to print scaffolds designed to prevent the collapse of complex structures.

Asepsis room technique

Cellink's proprietary aseptic operation room technology enables Inkredible + to be operated outside of the biological laboratory, thus giving birth to a true desktop-grade biological 3D printer. An HEPA filter ensures a sterile environment inside your bio-printer by making the cabin air pressure greater than the air pressure outside.

UV UV crosslinking curing system

The UV UV crosslinking curing system strengthens the structure so that it can be moved without being damaged. The Inkredible + device is standard equipped with a 365nm wavelength UV LED, with the option of a 405nm wavelength for further expanding the range of bio-ink crosslinking curing.

conclusion

Bioprinted human tissues and organs are revolutionizing the field of tissue engineering. It will cover subjects such as life sciences, medicine and materials. It requires a systematic technical foundation and a cross-disciplinary approach to promote the research, transformation and application of this new technology in hospitals. We believe that by collaborating with scientists around the world, the bio-printer will be able to serve humanity better.