Composition classification

①Pure iron and low carbon steel

Carbon content is less than 0.04%, including electromagnetic pure iron, electrolytic iron and carbonyl iron. It is characterized by high saturation magnetization, low price, and good processing performance; but its resistivity is low, and the eddy current loss is large under an alternating magnetic field. It is only suitable for static use, such as manufacturing electromagnet cores, pole shoes, relays and speaker magnets. Conductor, magnetic shield, etc.

②Fe-Si alloy

The silicon content is 0.5% to 4.8%, and it is generally used as a thin plate, commonly known as silicon steel sheet. After adding silicon to pure iron, it can eliminate the phenomenon that the magnetism of the magnetic material changes with the use time. With the increase of silicon content, the thermal conductivity decreases, the brittleness increases, and the saturation magnetization decreases, but its resistivity and permeability are high, and the coercive force and eddy current loss decrease, so it can be applied to the AC field, manufacturing motors, transformers, Iron cores for relays, transformers, etc.

③Iron-aluminum alloy

Containing 6% to 16% aluminum, it has good soft magnetic properties, high permeability and resistivity, high hardness and good wear resistance , But brittle, it is mainly used to manufacture iron cores, magnetic heads, ultrasonic transducers, etc. of small transformers, magnetic amplifiers, relays, etc.

④Fe-Si-Al alloy

It is obtained by adding silicon to the binary iron-aluminum alloy. Its hardness, saturation magnetic flux density, permeability and resistivity are all high. The disadvantage is that the magnetic properties are sensitive to composition fluctuations, brittleness is large, and processing performance is poor. Mainly used for audio and video heads.

⑤Nickel-iron alloy

Nickel content is 30%~90%, also known as Permalloy. Through alloying element ratio and proper technology, magnetic properties can be controlled and high Soft magnetic materials such as magnetism, constant magnetism, moment magnetism, etc. It has high plasticity and is more sensitive to stress. It can be used as pulse transformer material, inductor core and functional magnetic material.

⑥Iron-cobalt alloy

The cobalt content is 27%-50%. It has high saturation magnetization and low resistivity. Suitable for manufacturing pole shoes, motor rotors and stators, small transformer cores, etc.

⑦Soft ferrite

Non-metal ferrimagnetic soft magnetic material. The resistivity is high (10-2~1010Ω·m), the saturation magnetization is lower than that of metal, and the price is low. It is widely used as inductance components and transformer components (see ferrite).

⑧Amorphous soft magnetic alloy

A non-long-range ordered, non-crystalline alloy, also known as metallic glass, or amorphous metal. Its magnetic permeability and resistivity are high, coercive force is small, it is not sensitive to stress, there is no magnetocrystalline anisotropy caused by crystal structure, and it has the characteristics of corrosion resistance and high strength. In addition, its Curie point is much lower than that of crystalline soft magnetic materials, and the power loss is greatly reduced. It is a new type of soft magnetic material that is being developed and utilized.

⑨Ultramicrocrystalline soft magnetic alloy

A soft magnetic material discovered in the 1980s. Composed of a crystalline phase less than 50 nanometers and an amorphous grain boundary phase, it has better overall performance than crystalline and amorphous alloys, not only has high permeability, low coercivity, low iron loss, and saturation High magnetic induction intensity and good stability. The main research is iron-based ultra-microcrystalline alloys.

Performance parameters

Saturation magnetic induction intensity Bs: Its magnitude depends on the composition of the material, and its corresponding physical state is the orderly arrangement of the magnetization vector inside the material.

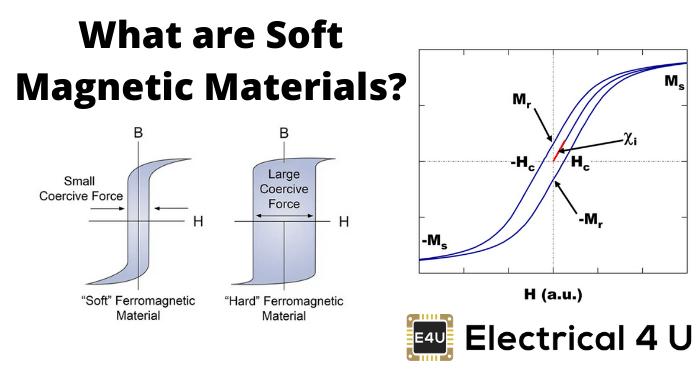

Residual magnetic induction Br: is the characteristic parameter on the hysteresis loop, the value of B when H returns to 0.

Rectangle ratio: Br∕Bs

Coercivity Hc: It is the amount that indicates the difficulty of magnetization of the material, which depends on the composition and defects of the material (impurities, stress, etc.).

Permeability μ: is the ratio of B to H corresponding to any point on the hysteresis loop, which is closely related to the working state of the device.

Initial permeability μi, maximum permeability μm, differential permeability μd, amplitude permeability μa, effective permeability μe, pulse permeability μp.

Curie temperature Tc: The magnetization of a ferromagnetic substance decreases with increasing temperature. When a certain temperature is reached, the spontaneous magnetization disappears and turns into paramagnetism. The critical temperature is the Curie temperature. It determines the upper limit temperature of the magnetic device.

Loss P: Hysteresis loss Ph and eddy current loss Pe P = Ph + Pe = af + bf2+ c Pe ∝ f2 t2 /, ρ decreases,

Reduce hysteresis loss Ph The method is to reduce the coercivity Hc; the method to reduce the eddy current loss Pe is to thin the thickness t of the magnetic material and increase the resistivity ρ of the material. The relationship between the loss of the magnetic core and the temperature rise of the magnetic core in free still air is:

Total power dissipation (mW)/surface area (cm2)

New soft magnet

Soft ferrite

The characteristics of soft ferrite are: low saturation magnetic flux density, low permeability, low Curie temperature, low medium and high frequency loss, and low cost. The first three lows are its shortcomings, which limit its scope of use. Now (the beginning of the 21st century), efforts are being made to improve. The latter two lows are its advantages, which are conducive to entering the high-frequency market. Now (the beginning of the 21st century) is working hard to expand.

Taking the loss at 100kHz, 0.2T and 100℃ as an example, TDK's PC40 is 410mW/cm3, PC44 is 300mW/cm3, and PC47 is 250mW/cm3. TOKIN's BH1 is 250mW/cm3, and the loss is constantly decreasing. The domestic JP4E produced by Jinning also reached 300mW/cm3.

Continuously increasing the working frequency is another direction of effort. The operating frequency of TDK's PC50 is 500kHz to 1MHz. FDK's 7H20 and TOKIN's B40 can also work at 1MHz. Philips' 3F4, 3F45, and 3F5 operating frequencies are all over 1MHz. The operating frequencies of domestic Jinning’s JP5 and Tiantong’s TP5A both reach 500kHz to 1.5MHz. The operating frequency of DMC's DMR1.2K even exceeds 3MHz, reaching 5.64MHz.

Permeability is the weak item of soft ferrite. Now (the beginning of the 21st century) domestically produced products are generally around 10,000. The H5C5 of foreign TDK company and the 3E9 of Philips company reached 30,000 and 20,000 respectively.

The research of using SHS method to synthesize MnZn ferrite materials is worth noting. The test results of this method show that the energy consumption and cost of ferrite manufacturing can be greatly reduced. There have been reports of successful trials in China.

Amorphous and nanocrystalline alloys

Iron-based amorphous alloys are competing with silicon steel in the power and intermediate frequency fields. Compared with silicon steel, Fe-based amorphous alloy has the following advantages and disadvantages.

1) The saturation magnetic flux density Bs of the iron-based amorphous alloy is lower than that of the silicon steel. However, under the same Bm, the loss of the iron-based amorphous alloy is smaller than that of the 0.23mm thick 3% silicon steel. It is generally believed that the reason for the low loss is the thin thickness and high resistivity of the iron-based amorphous alloy strip. This is just one aspect. The more important reason is that the iron-based amorphous alloy is amorphous, and the atomic arrangement is random. There is no magnetocrystalline anisotropy caused by the oriented arrangement of atoms, and there is no crystal that produces local deformation and composition shift. Grain boundary. Therefore, the energy barrier that hinders the domain wall movement and the rotation of the magnetic moment is very small, and it has unprecedented soft magnetism, so the magnetic permeability is high, the coercive force is small, and the loss is low.

2) The filling factor of the iron-based amorphous alloy core is 0.84~0.86. Compared with the filling factor of silicon steel of 0.90~0.95, the volume of the iron-based amorphous alloy core of the same weight is larger than that of the silicon steel core.

3) The working magnetic flux density of the iron-based amorphous alloy core is 1.35T to 1.40T, and the silicon steel is 1.6T to 1.7T. The weight of the iron-based amorphous alloy power frequency transformer is about 130% of the weight of the silicon steel power frequency transformer. However, even if the weight is heavy, for a power frequency transformer of the same capacity, the loss of the iron-based amorphous alloy core is 70% to 80% lower than that of silicon steel.

4) It is assumed that the load loss (copper loss) of the power frequency transformer is the same, and the load rate is also 50%. Then, if the iron loss of the silicon steel power frequency transformer is the same as that of the iron-based amorphous alloy power frequency transformer, the weight of the silicon steel transformer is 18 times that of the iron-based amorphous alloy transformer. Therefore, regardless of the loss level of the transformer, the average domestic people agree on the weight, cost and price of the iron-based amorphous alloy power frequency transformer, which is 130% to 150% of the silicon steel power frequency transformer, which does not meet the market requirements. The principle of performance-price ratio. Two methods of comparison are proposed abroad. One is to calculate the weight and price of the copper and iron materials used in the two power frequency transformers under the same loss conditions and compare them. Another method is to reduce the wattage of the loss of the iron-based amorphous alloy power frequency transformer and convert it into currency to compensate. The no-load loss per watt is converted to USD 5-11, which is equivalent to RMB 42-92. The load loss per watt is converted into USD 0.7-1.0, which is equivalent to RMB 6-8.3. For example, a silicon steel magnetic core for a 50Hz, 5kVA single-phase transformer is quoted at 1700 yuan/unit; no-load loss is 28W, calculated at 60 yuan/W, which is 1680 yuan; load loss is 110W, calculated at 8 yuan/W, which is 880 yuan; then, the total assessed price is 4260 yuan/unit. With iron-based amorphous alloy cores, the price is 2500 yuan/unit; the no-load loss is 6W, which is equivalent to RMB 360; the load loss is 110W, which is equivalent to RMB 880, and the total estimated price is 3740 yuan/unit. If you do not consider the loss, just calculate the quotation, the 5kVA iron-based amorphous alloy power frequency transformer is 147% of the silicon steel power frequency transformer. If the loss is considered, the total estimated price is 89%.

5) Now (the beginning of the 21st century) the test of the core material loss of the power frequency power transformer is carried out under a sine wave voltage with a distortion less than 2%. The actual power frequency grid is distorted to 5%. In this case, the loss of iron-based amorphous alloy increased to 106%, and the loss of silicon steel increased to 123%. If the high-order harmonics are large and the distortion becomes 75% (for example, the power frequency rectifier transformer), the loss of the iron-based amorphous alloy increases to 160%, and the loss of silicon steel increases to more than 300%. It shows that the iron-based amorphous alloy has stronger resistance to power waveform distortion than silicon steel.

6) The magnetostriction coefficient of iron-based amorphous alloy is large, which is 3 to 5 times that of silicon steel. Therefore, the noise of the iron-based amorphous alloy power frequency transformer is 120% of that of the silicon steel power frequency transformer, which is 3~5dB larger.

7) In the current market, the price of iron-based amorphous alloy strip is 150% of 0.23mm3% oriented silicon steel and about 40% of 0.15mm3% oriented silicon steel (after special treatment).

8) The annealing temperature of iron-based amorphous alloy is lower than that of silicon steel, and it consumes less energy, and iron-based amorphous alloy cores are generally manufactured by specialized manufacturers. Silicon steel magnetic cores are generally manufactured by transformer manufacturers.

According to the above comparison, as long as it reaches a certain production scale, iron-based amorphous alloys will replace part of the silicon steel market in electronic transformers in the power frequency range. In the mid-frequency range of 400Hz to 10kHz, even if new silicon steel varieties appear, iron-based amorphous alloys will still replace most of the silicon steel market with a thickness of less than 0.15mm.

It is worth noting that Japan is vigorously developing FeMB-based amorphous alloys and nanocrystalline alloys, the Bs of which can reach 1.7 ~ 1.8T, and the loss is less than 50% of the existing FeSiB-based amorphous alloys. If it is used in power frequency electronic transformers, the working magnetic flux density is above 1.5T, and the loss is only 10% to 15% of silicon steel power frequency transformers, it will be a more powerful competitor of silicon steel power frequency transformers. Japan is expected to successfully trial-produce FeMB-based amorphous alloy power frequency transformers and put them into production in 2005.

Amorphous nanocrystalline alloys are competing with soft ferrite in the medium and high frequency field. In the 10kHz to 50kHz electronic transformer, the working magnetic flux density of the iron-based nanocrystalline alloy can reach 0.5T, and the loss P0.5/20k≤25W/kg. Therefore, it has obvious advantages in high-power electronic transformers. In the 50kHz to 100kHz electronic transformer, the iron-based nanocrystalline alloy loss P0.2/100k is 30~75W/kg,

The iron-based amorphous alloy P0.2/100k is 30W/kg, which can be substituted Part of the ferrite market.

After more than 20 years of popularization and application of amorphous nanocrystalline alloys, it has been proved that it has the following advantages:

1) There is no problem of aging stability, and nanocrystalline alloys are below 200℃ , Cobalt-based amorphous alloys have no significant changes in performance after long-term use under 100℃;

2) The temperature stability is better than soft ferrite, and the magnetic properties are within the range of -55℃ to 150℃. It can change by 5%~10% and is reversible;

Soft magnetic composite materials

After controversy, now (the beginning of the 21st century) there has been a consensus on magnetic powder cores, that is, It belongs to soft magnetic composite material. Soft magnetic composite materials are formed by uniformly dispersing magnetic particles in non-magnetic materials. Compared with traditional metal soft magnetic alloys and ferrite materials, it has many unique advantages: magnetic metal particles are dispersed in non-conductor objects, which can reduce high-frequency eddy current loss and increase application frequency; it can be processed by hot pressing Powder cores can also be injection molded into magnets with complex shapes using current (early 21st century) plastic engineering technology; it has the advantages of low density, light weight, high production efficiency, low cost, and good product repeatability and consistency. The disadvantage is that the magnetic particles are separated by non-magnetic bodies and the magnetic circuit is cut off. The magnetic permeability is generally less than 100 now (in the early 21st century). However, using nanotechnology and other measures, there have been reports of magnetic permeability exceeding 1,000 in foreign countries, up to 6,000.

The magnetic permeability of soft magnetic composite materials is affected by many factors, such as the composition of magnetic particles, particle shape, size, packing density, etc. Therefore, it can be adjusted according to the operating frequency.

Magnetic powder core is a typical example of soft magnetic composite materials. Now (at the beginning of the 21st century) some soft ferrites have been replaced in inductors ranging from 20kHz to 100kHz or even 1MHz. For example, sendust magnetic powder core, silicon content is 8.8%, aluminum is 5.76%, and the rest is all iron. The particle size is 90~45μm, 45~32μm and 32~30μm. Use silicone resin as adhesive and 1% stearic acid as lubricant. Under the pressure of 2t/cm2, a 13×8×5 ring magnetic core is made. Use 673°K, 773°K, 873 in hydrogen. °K annealing to make the permeability reach 100, 300, 600. Low loss at 100kHz, it has been used in inductors instead of soft ferrite and MPP powder cores.

Someone has developed and researched the soft magnetic composite material-magnetic powder core for inductors of high-power power supplies. Below 20kHz, the permeability is basically unchanged. At 1.0T, the permeability is about 100. The 50Hz~20kHz loss is small, and it can be made into a large magnetic core weighing more than 100kg, and in the audio frequency range of 20kHz, the noise is reduced by 10dB compared to the toroidal ferrite core. It can replace silicon steel and soft ferrite in high-power power supplies.

Some people use cobalt/silica (Co/SiO2) nanocomposite soft magnetic materials to make large-size magnetic cores that are different from thin films. The average size of the cobalt particles is 30μm, and the filling degree is 40% to 90%. After stirring, the cobalt particles are annealed to form Co/SiO2 nanocomposite powder, which is then pressed into a toroidal magnetic core. The magnetic permeability can reach 16 below 300MHz. The permeability of nickel-zinc ferrite is 12, and it drops rapidly after 100MHz. It proves that under high frequency and ultra high frequency, soft magnetic composite materials can also replace part of the ferrite market.

Research progress

In recent years, there has been a trend of using electric drive devices and electronic control devices to realize product drive, automatic control and multi-function. One of the key core materials is Soft magnetic materials. Soft magnetic materials play the role of energy coupling transfer and conversion in various devices. In today's increasingly scarce energy and environmental problems, reducing the loss of soft magnetic materials and improving the efficiency of the magnetic core is of great significance in saving energy and controlling environmental pollution.

Since the 1990s, the development of soft magnetic materials has gone through a glorious page: amorphous, nanocrystalline, metallic glass soft magnetic materials, magnetic powder cores, amorphous microcrystalline strips, soft magnetic composites Materials bring hope to energy conservation and emission reduction in countries around the world that are paying more and more attention to environmental and energy issues. Soft magnetic materials are of great significance in miniaturization and high performance in the fields of automobiles, new energy, information, consumer electronics, and power electronics. We need to strengthen our foundation, explore courageously, conduct innovative research, and strive for international magnetism in the future. In the field of materials, China's independent intellectual property rights account for a considerable proportion.

Development trend

Electronic devices are increasingly developing towards miniaturization, high performance, and high speed. Therefore, new requirements are put forward for high frequency inductance components, and further improvements and enhancements are required as inductors. The performance of the ferrite core of the component has higher requirements for soft magnetic materials and core components. A good soft magnetic material should meet the following basic requirements: (1) In order to improve the functional efficiency, the initial permeability and the maximum permeability should be high; (2) In order to save resources, it is convenient to be light, thin and short, and quickly respond to the polarity of the external magnetic field. Reversal, the residual magnetic flux density should be low, and the saturation magnetic induction should be high; (3) Low loss, improve functional efficiency; (4) Small coercivity, improve high-frequency magnetic performance; (5) High resistivity, improve high-frequency Performance, reduce eddy current loss; (6) Low magnetostriction coefficient, reduce noise; (7) The basic characteristic of magnetic anisotropy coefficient K should be low, easy to magnetize in all crystal directions.

From the changes in the production of soft magnetic materials in various countries in recent years, it can be seen that the world's production pattern of soft magnetic materials has undergone great changes. There will still be a substantial increase in output, but competition will become more intense. Therefore, how to reduce costs, improve efficiency, improve product quality and market competitiveness will become the key to competition.

The materials with the greatest demand and the most urgent requirements for performance improvement are high-frequency low-power loss ferrite materials and high-permeability ferrite materials. High-frequency low-power loss ferrite materials are mainly used in various high-frequency miniaturized switching power supplies, displays, and transformers. High permeability ferrite materials are mainly used for anti-electromagnetic wave interference devices for broadband transformers and pulse transformers.

Fundamentally speaking, the microstructure of a material determines its macroscopic properties. Therefore, the magnetic quantum theory should be used as a guide to analyze and improve the microstructure of the material to improve its macroscopic magnetic properties. The research on soft magnetic materials has shifted from coarse-grained to nano-crystalline alloy material preparation and composition design. The research of nanomaterials and the science of material design are developed based on this macro-magnetic performance idea, that is, material design is based on the first principles. In terms of magnetic materials, with the development of modern science and technology, quantum theory has The successful interpretation of spin-ordered materials and the combination of quantum theory and micromagnetism have gradually achieved the goal of high saturation magnetic induction and low loss soft magnetism.

Nanotechnology has brought leaps and bounds to the traditional magnetic industry. The advantage of using the excellent performance and special structure of nanomaterials to comprehensively improve the comprehensive performance of traditional soft magnetic materials is that without major technical transformation of existing equipment, it is possible to comprehensively improve the technical content and technical content of traditional materials for enterprises. The purpose of the quality level.

In short, the development of soft magnetic materials will develop along the direction of high saturation magnetic induction, high permeability, high Curie temperature, low loss, low coercivity and high frequency, miniaturization, and thinning. . The soft ferrite material is further developed to high frequency, high permeability and low loss. Amorphous and nanocrystalline soft magnetic alloys will develop new and functional amorphous and nanocrystalline composite materials to broaden the application fields of amorphous and nanocrystalline composite materials.