Background

In large-scale turbo-generators and large-scale high-voltage AC motors, due to stator winding failures (such as insulation wear, wiring open welding, strand breaks, high electric fields cause corona Etc.) will cause the internal discharge of the generator to increase during operation. In severe cases, the arc will be generated at the discharge, which will cause local overheating and damage the insulation of the winding to the ground, which will seriously affect the insulation life of the generator.

In a sense, the generator body is a discharge body. For the air gap or bubbles inside the insulation, the energy of local and repeated breakdown and extinction under a certain applied voltage is relatively high. The small partial discharge phenomenon does not affect the short-term insulation strength of the equipment. However, the undesirable effects of these weak discharge energy, accumulating over time, can eventually lead to the breakdown of the entire insulation. In order to prevent the occurrence of such catastrophic accidents, it is very necessary to detect partial discharges online without affecting the normal operation of large generator sets.

Monitoring method

Partial discharge monitoring of generators

The equipment for continuous and uninterrupted partial discharge monitoring of generators. There are two widely used measurements Method 4. One is, ParticialDischargeMonitoring, which uses traditional partial discharge monitoring methods; the other is Radiofrequency(RF)Monitoring, which was introduced in 1985 The United States Westinghouse technology device 11, most of the domestic and foreign units with a capacity of 600 MW and above use radio frequency methods.

The goal of the two methods is to detect partial discharge, and the methods adopted are different. The online monitoring of generators introduced at the EPRI (Electrical Research Institute) Online Monitoring and Diagnosis Conference in the United States in 2001 also used the Radio Frequency Monitoring Bureau. Put method.

Main products

SJY series radio frequency monitor

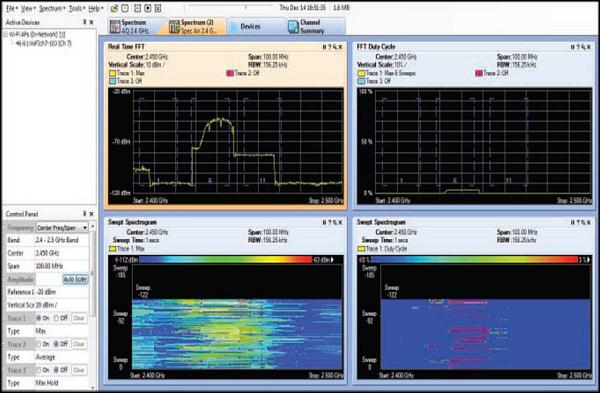

SJY series radio frequency monitor includes high frequency current transformer, monitor host and remote control board. The high-frequency signal of the arc on the neutral point of the generator is monitored by the high-frequency current transformer to find the discharge phenomenon in the stator coil. The radio frequency monitor is coupled to the radio frequency signal from the high frequency current transformer. By amplifying and processing the weak radio frequency signal, the strength of the discharge current can be monitored, so as to detect the degree of partial discharge of the generator, and realize the effect of the generator stator Insulation status monitoring and fault alarm. The RF signals of SJY-3 and SJY-5 RF monitors enter the DCS system, and the remote control board installed in the centralized control room is equipped with a high-end processor digital graphics recorder based on the ARM core to achieve high-speed information acquisition and processing, and large-capacity flash memory The chip can realize long-term data storage. Display graphics on 240X128 dot matrix LCD graphic display, and readings of 0-100% and 10μV-10,000μV. Use USB interface storage body to backup or dump historical data and communication function.

SJY-5 radio frequency monitor has been used for 8 domestically produced 1,000MW thermal power units such as Yuhuan, Waigaoqiao, Beilun, etc. The SJY series radio frequency monitor has experienced nearly 300 sets in 125MW-650MW thermal power plants. Tests and experience accumulation of reliable operation on, hydropower, and nuclear power units [1], [2], [3], it can monitor and diagnose the insulation status of ultra-supercritical technology million kilowatts, large capacity, high-parameter units, is right Recognition and marking of radio frequency monitoring technology.

This is based on the fact that the power system is developing digitization, and more advanced means are required for unified management of information. The SJY-1 remote control board is equipped with a mechanical recorder, which records a single radio frequency signal on paper. Above, when the alarm recall is required, the time interval is more difficult to distinguish, and it is difficult to correspond to other working conditions of the generator. After the signal enters the DCS system, other related data can be displayed on the same page, which is conducive to the analysis of the event by the alarm recall. The recording graph of the SJY radio frequency monitor on the DCS system of the imported 600MW generator set of Beilun Power Plant, the same page also displays other working condition parameters such as generator power.

The SJY-1 radio frequency monitor is upgraded to the recording graphics of the DCS system, and the successive damage accidents of the main exciter rotor and related parts are recorded. The technical level is not yet able to predict emergencies, and the on-line radio frequency monitoring instrument signals are connected to the DCS system to play a similar role as a "black box" when recalling accidents.

The phase-to-phase and phase-to-ground arcs appear at the end of the armature winding on the side of the rectifier disk, which burns out the coil, insulation and residual hoops at the end of the armature. At the same time, the secondary excitation is severely swept away. Burned out, and the outside of the rotor armature latitude belt tying hoop shows that the Shanghai Wujing No. 2 Power Plant upgraded the SJY-1 radio frequency monitor to the record pattern of the DCS system, and recorded the successive damage accidents of the main exciter rotor and related components. .

This system has a secondary diagnosis function. The first-level diagnosis is performed online, and the SJY-1 radio frequency monitor is used to monitor the insulation status of the generator. When the indicating signal value exceeds the standard or abnormal, it will be used as the start of the next-level diagnosis; the second-level diagnosis is offline Yes, it is a question-style interactive diagnosis.

In view of the current bottleneck problem of knowledge acquisition in expert systems, the knowledge-based multivariate fuzzy diagnosis method is adopted, based on radio frequency monitoring, and the generator working condition parameters such as temperature, dew point and vibration are integrated. , From the overall to the partial analysis and synthesis, the combination of online monitoring and offline testing, effectively analyze and process various incomplete information such as inaccuracy and incompleteness, and discover hidden knowledge from it, revealing potential laws. The generator failure The historical data is firstly fuzzy processed, and then the fault diagnosis decision table is constructed. The decision table is used as the main tool, that is, the "knowledge base" uses fuzzy logic diagnosis to directly extract potential diagnosis rules from the decision table to provide the turbo generator system. Effective fault diagnosis.

The system can perform fuzzy reasoning (inaccurate reasoning) in the presence of uncertainty and insufficient information. The environment in which the system problem is solved is not static and can handle dynamic variable input. The dynamic knowledge base is expandable and modifiable.

Correspondence between RF signal and generator system insulation status

The relationship between the signal indication value of the RF monitor and its development trend and the status of the generator is divided into good, intermediate transition, attention , Warning and Dangerous areas.

When the signal of the radio frequency monitor is lower than 50% of the upper indication value (that is, the input signal of the radio frequency instrument is less than 300μV), it indicates that the insulation state of the generator system is good, which is shown in green in Figure 2; when the signal is in Between 66.6-80% (that is, the input signal of the corresponding radio frequency instrument is in the range of 1000-3000μV), attention should be paid to the insulation condition of the generator system, and the change trend is observed. The indicator is indicated in orange on the table; when the signal is greater than 80%, in this area It is a warning or critical state, which is indicated in red. It should be taken seriously, and its changes should be paid close attention to. The pre-alarm and alarm thresholds are set at 75% and 90%, respectively. When alarming, change the dependence of load observation and load change, and stop processing if necessary. Practical experience shows that the change characteristics and trends of radio frequency signals contain more information.

Relevant information was obtained from 41021653 without permission