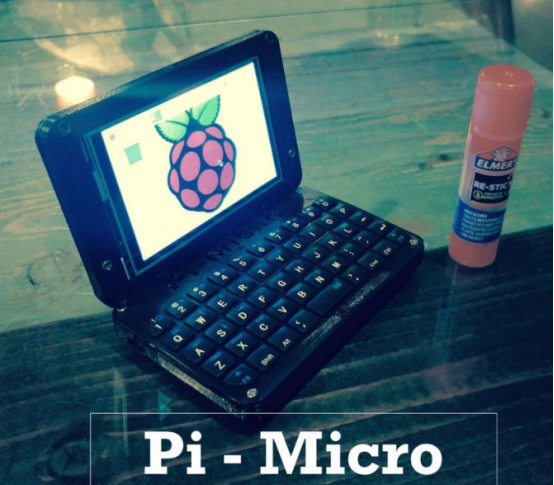

Have you ever thought about making a computer that can be placed in the palm of your hand? I really wanted to, so I made this small laptop that I call Pi-Micro. This is the third edition of Pi-Micro. It has been produced for nearly a year. Because it is sufficiently detailed, I will share it with you. Pi-Micro can run a complete Linux operating system. Be able to browse the web, edit documents, use the terminal, create custom programming scripts, and play games.

As far as I know, it is the smallest computer made with Raspberry Pi, and it also has a full keyboard. Made with Raspberry Pi Zero W, built-in WiFi and Bluetooth.

Pi-Micro specification introduction:

512 MB RAM

1GHz processor

Built-in WiFi and Bluetooth

3.5" touch screen

1000mAh lithium ion built-in battery

16GB internal storage

Complete QWERTY keyboard 108mmX19.5mmX70mm

The mental journey of making Pi-Micro

(If you want dry goods, please skip this part directly.)

This laptop has been polished for more than a year. During this year, I experienced many different versions of designs and prototypes. The first two models I designed are heavy, and the weight of the two rotating shafts is not suitable for the screen/motherboard.

a.V1.0 (black) My first version of Pi-Micro was made on May 6, 2017. It uses a 3D printed rotating shaft, which is too loose to allow the screen to stand on its own. But its keyboard is built-in which I like, but it is very thick and bulky. The edges of the top and bottom of the box are not round, and the shell is very cheap.

b.V2.0 (Blue) My second version of Pi-Micro was produced around October 2017. I tried to fix this problem with rotating shafts made of ultra-small brass, but they were still too loose. In this version, in order to make it look more beautiful, I turned all the edges into circles, and made interfaces for the Raspberry Pi in a 3D modeling program, instead of soldering iron interfaces. One unique thing about this version is that the connection between the rotating shaft and the keyboard can be disassembled up and down at will. However, I didn't like its appearance in the end, because it didn't look like a laptop.

Project disclaimer

The best projects are never easy. For this handheld computer, it took me more than a year to get the current product after several versions and several revisions. This project has a lot of difficult soldering/desoldering, and a basic understanding of Linux and Raspberry Pi. If you are injured yourself or anything else, I am not responsible. Please always wear appropriate protective devices, do not connect the red and black wires, and never puncture the battery. carefully!

3D printing shell

The model file can be downloaded in the project file library.

http://make.quwj.com/project/44 The

printing parameters are set as follows:

filament: ESUN PLA +

thickness: 0.2MM

shell: 3

filling: 80%

Component list

Raspberry Pi Zero W × 1

3.5 inch touch screen monitor × 1

3D printer × 1

Power bank × 1

Mini Bluetooth keyboard × 1

Micro SD card × 1

USB socket × 1

Sewing needle × 2

Wire × 1

Screw × 1

Glue × 1

Disassemble the power bank

The purpose of disassembly is to obtain a slim battery/charger combination, power switch, and 5v output.

Step 1, remove the screws from the chassis, and then remove the internal components from the aluminum shell.

Step 2, cut the wires from the solar panel to the controller board.

Step 3, disconnect the battery, and then reconnect the two 3-inch wires between it and the controller board.

Step 4, remove the USB port, and weld the welding wires to the positive and negative output terminals of the controller board.

Prepare screen components

Important note: This step is based on Waveshare 3.5" monitor. If you use a different monitor, please change the soldered wire pins to meet your monitor specifications. For

more details, see the link under the article

1. Remove the casing on the touch screen. Just me Personally, the easiest way is to cut it off with a flushing knife, and then use a soldering iron to individually remove the lower part of the pin from the circuit board.

2. Solder the wires to the pins 1,2,6,11,18 , 19, 21, 22, 23, 24 and 26.

3. Mark all the wires so that you can distinguish clearly, as shown in the picture.

4. Check the labels carefully.

5. Drill holes in the 3D printed display parts so that they can be Combine it together.

6. Check the label again. Trust me, it will save a lot of frustration.

7. Place the screen inside the part and group it together.

Solder the USB socket to the Raspberry Pi

I installed the USB interface in the lower right corner of the computer.

1. First use wire cutters to cut off the small labels on both sides of the USB jack (not any of the four pins), because they are not used to fix the USB.

2. Bend the four pins downward at a 90-degree angle so that they extend out of the back, but the socket does not extend out of the bottom.

3. Solder wires to each pin, make sure they are long enough to extend from one side of the housing to the other, and if necessary, insulate the ports with heat shrink tubing. Tip: Use wires of different colors; it helps to distinguish which ones you want to connect to the Pi.

4. Using the circuit diagram above, solder the wires to the Pi's pads.

Soldering the battery to the Raspberry Pi

1. Solder the red wire from the power supply 5V output Pi 5V pin.

2. Solder the black wire of the power supply GND output to the Pi GND pin.

Soldering the screen to the Raspberry Pi

This step is very tricky, so be careful.

1. Please shorten the wire length as much as possible. If your wires are too long, they will accumulate in the bottom case, making it difficult to close. Try to measure the distance required for each wire and cut them accurately so that when the display and the lower half are arranged, there will be a 2CM gap between the edge of the bottom case and the edge of the display.

2. Connect the labeled wires to the corresponding pins on the Pi. Please confirm each lead.

install software

You need at least a 8GB Micro SD card, but the size you choose to use will determine the Pi-Micro's internal storage capacity.

This is an important step because it also helps to determine whether the screen and battery are connected properly.

1. Format the Micro SD as FAT32.

2. Download the pre-made system image for Waveshare displays here .

3. Use Etcher to write the system image to the Micro SD.

4. Insert the card into the Pi, turn on the battery and wait for the good news.

5. If everything goes well, it means your installation is correct. If there is a problem, please check all solder joints and wiring carefully.

6. Pair the Bluetooth keyboard with Pi. This means that we don't have to access the pairing button on the keyboard later, and it will automatically connect every time it starts.

Reduce the size of the keyboard and solder it to the Raspberry Pi

For Pi-Micro's keyboard, we will use a battery-based mini Bluetooth keyboard and then solder it to the Pi.

1. Open the keyboard shell. I found that the easiest way is to bend the keyboard until a crack appears between the top and bottom of the box, and then pry it open with a flat-head screwdriver.

2. Remove the micro USB charging port. Heat directly behind the port and use a soldering iron to complete this operation. When the solder melts, it will easily slip off.

3. Remove the battery.

4. Solder the two wires to the battery port for connection.

5. Open it. (When we connect it to the Pi, make sure it will be turned on at the same time.)

6. Solder the wire from the positive terminal of the battery to the 3.3V pin on the Pi

7. Solder the wire from the negative terminal of the battery to anything on the Pi GND pin.

Assemble all components

Tip: This is the most troublesome part, so please be patient. For the rotating shaft part, I decided to use a needle as the rotating shaft. If there is resistance during the entire installation process, do not forcefully squeeze it. It is much better to tidy up the contents of the shell than to pull it hard.

1. Make sure everything is the right size. Put all the components in the case, put the cover on the lower part, and make sure it is flush. If not, please fine-tune it.

2. Use hot glue to fix everything (except the battery, which may explode). This way you can ensure that there will not be any displacement when you shake the completed computer, and you will not push it into the computer when you try to use the USB and charging ports.

3. Now everything is safe, put the cover on the lower part and fix it with screws. You may need to pre-drill the holes because the thickness of the screws that can be used is different, so I didn't put these holes in the design.

4. Place the display on the lower part. Make sure it can be installed on the bottom rotating shaft and can rotate.

5. Install the needle. I recommend using the needles with the largest diameter. Since the rotating shaft will harden, you may need to use the tip of a piece of wood or something to push them.

6. If necessary, use a soldering iron to melt the plastic at both ends of the needle to avoid slipping out.

7. If necessary, go around the bottom of the lower part and the edge of the lid, and use a soldering iron to solder any gaps.

DONE! It's done! Hope friends like this project!