Function

The function of the crank connecting rod mechanism is to provide a combustion place, and convert the expansion pressure of the gas produced by the fuel combustion on the top of the piston into the torque of the crankshaft rotation, which is continuously output power.

(1) Change the pressure of the gas into the torque of the crankshaft

(2) Change the reciprocating motion of the piston into the rotational motion of the crankshaft

(3 ) The combustion force acting on the top of the piston is converted into the torque of the crankshaft to output mechanical energy to the working machine.

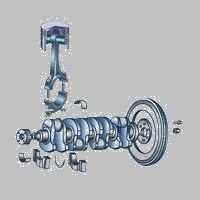

Composition

The crank-connecting rod mechanism consists of the body group, the piston connecting rod It consists of three parts: the crankshaft flywheel assembly.

(1) Body set: cylinder block, cylinder head gasket, cylinder head, crankcase, cylinder liner and oil pan

(2) Piston connecting rod set: piston, piston ring , Piston pin, connecting rod

(3) Crankshaft flywheel set: crankshaft, flywheel, torsion damper, balance shaft

Body set

The body is composed The skeleton of the engine is the installation foundation for the various mechanisms and systems of the engine. All the main parts and accessories of the engine are installed inside and outside, which bear various loads. Therefore, the body must have sufficient strength and rigidity.

Cylinder block

The cylinder block is the assembly base of the various mechanisms and systems of the engine, and is the most important part of the engine. The cylinder block has a water-cooled cylinder block and an air-cooled cylinder block.

The water-cooled cylinder block is generally cast as a whole with the upper crankcase. All the cylinders are shot out on the upper part of the cylinder block, and the cavities around the cylinders are connected to each other to form a water jacket. The lower part is the crankcase used to support the crankshaft.

The cylinder block has three types: in-line, V-shaped and horizontally opposed, and in-line and V-shaped are commonly used in automobiles. The structure of the lower part of the cylinder block has three forms: general type, gantry type, and tunnel type. Air-cooled cylinder block and crankcase adopt a split structure. The cylinder block and crankcase are cast separately and then assembled together. There are many cooling fins cast on the outer surface of the cylinder block and cylinder head to ensure sufficient heat dissipation. The material of the cylinder block is generally gray cast iron. In order to improve the wear resistance of the cylinder, a small amount of alloying elements such as nickel, molybdenum, chromium and phosphorus are sometimes added to the cast iron. Wait. However, in fact, except for the surface of the cylinder wall that cooperates with the piston, other parts do not require high wear resistance. For material economy, it is widely used to insert the cylinder liner into the cylinder body to form the cylinder working surface. In this way, the cylinder liner can be made of alloy cast iron or alloy steel with better wear resistance to prolong the service life of the cylinder, and the cylinder block can be made of ordinary cast iron or aluminum alloy materials with lower prices. There are two types of cylinder liners, dry type and wet type.

The outer surface of the dry cylinder liner is not in direct contact with cold water, and its wall thickness is generally 1 to 3 mm. The outer surface of the cylinder liner and the inner surface of the assembled cylinder adopt an interference fit.

The outer surface of the wet cylinder liner is in direct contact with the cooling water, and the cooling effect is good. Its wall thickness is thicker than that of dry cylinder liners, generally 5-9mm.

Cylinder head

The main function of the cylinder head is to close the upper part of the cylinder, forming a combustion chamber together with the top of the piston and the cylinder wall.

A cooling water jacket is cast in the cylinder head of a general water-cooled engine. The lower end of the cylinder head and the upper end of the cylinder block are in communication with the corresponding water jacket. The water circulation is used to cool the high temperature parts such as the combustion chamber wall. ; There are many cooling fins cast on the cylinder head of the air-cooled engine to reduce the temperature of the combustion chamber by increasing the cooling area.

The cylinder head of the engine should have intake and exhaust valve seat duct holes and intake and exhaust passages. Gasoline engine cylinder heads should also have spark plug holes, while diesel engines have holes for installing fuel injectors.

Cylinder head gasket

A cylinder gasket is installed between the cylinder head and the cylinder block. Its function is to ensure the seal between the cylinder head and the cylinder block and prevent the combustion chamber from leaking air and water jackets. water leakage.

Oil pan

The main function of the oil pan is to store oil and seal the crankcase. The oil pan has very little force and is generally stamped out of thin steel plate.

Piston connecting rod set

Piston connecting rod set consists of piston, piston ring, piston pin, connecting rod, connecting rod bearing and so on.

Piston

The function of the piston is to form a combustion chamber together with the cylinder head and cylinder wall, and to withstand the gas pressure in the cylinder. The force is transmitted to the connecting rod through the piston pin. Push the crankshaft to rotate.

Piston can be divided into three parts: head, ring groove and skirt.

Piston head The piston is an integral part of the combustion chamber, and its shape depends on the form of the combustion chamber. Common piston head shapes include flat top, concave top and convex top.

Piston ring groove The piston ring is installed in the piston ring groove. Gasoline engines generally have 2 to 3 ring grooves. The upper 1 or 2 grooves are used to install the gas ring to realize the sealing of the cylinder; the bottom one is used to install the oil ring. There are many radial oil return holes drilled on the bottom of the oil ring groove. When the piston moves down, the oil ring scrapes off the excess oil on the cylinder wall and flows back to the oil pan through the oil return hole. If the temperature is too high, the first ring is prone to carbon deposits, causing overheating and jamming.

Piston skirt The piston skirt plays a guiding role.

Piston ring

The piston ring is installed in the piston ring groove to seal the gap between the piston and the cylinder wall, prevent blow-by, and make the piston reciprocate smoothly. Piston rings are divided into two types: gas ring and oil ring.

Piston pin

The function of the piston pin is to connect the piston and the small end of the connecting rod, and transmit the gas force experienced by the piston to the connecting rod.

Piston pins are usually hollow cylinders, and sometimes they are made into cross-section tubular structures according to the requirements of equal strength.

Piston pins are generally made of low-carbon steel or low-carbon alloy.

The connection between the piston pin and the piston pin seat hole and the connecting rod small end bushing hole adopts full-floating and semi-floating connections. With full floating connection, the piston pin can rotate freely in the hole; with semi-floating connection, there is an interference fit between the pin and the small end of the connecting rod, and no relative rotation occurs during work; there is a gap between the pin and the piston pin seat hole Clearance fit.

Connecting rod

The function of the connecting rod is to transmit the force of the piston to the crankshaft and convert the reciprocating motion of the piston into the rotational motion of the crankshaft.

The connecting rod is composed of connecting rod body, connecting rod cover, connecting rod bolt and connecting rod bearing bush. The connecting rod body and connecting rod cover are divided into connecting rod small end, shaft and connecting rod big end.

The small end of the connecting rod is used to install the piston pin to connect the piston. The shaft is usually made into a "work" or "H"-shaped section to reduce the mass while meeting the requirements for strength and rigidity.

The big end of the connecting rod is connected with the connecting rod journal of the crankshaft. Generally, it is made into a separate type, and the half cut from the shaft is called a connecting rod cover, and the two are connected by connecting rod bolts as a whole.

The connecting rod bearing is installed in the big-end hole seat of the connecting rod and assembled with the connecting rod journal on the crankshaft. It is one of the most important matching pairs in the engine. Commonly used antifriction alloys mainly include white alloys, copper-lead alloys and aluminum-based alloys.

Crankshaft flywheel assembly

The crankshaft flywheel assembly is mainly composed of crankshaft, flywheel and some accessories.

Crankshaft

The crankshaft is one of the most important parts of the engine. Its function is to convert the gas force from the piston connecting rod group into the rotational torque of the crankshaft for external output, and to drive the engine's valve train and other auxiliary devices to work.

The front end of the crankshaft is mainly used to drive the air distribution mechanism, water pump and fan and other auxiliary mechanisms. The front shaft is equipped with timing gears (or timing pulleys), fan and water pump pulleys, and torsional vibration absorbers. As well as starting claws and so on.

The rear end of the crankshaft adopts a flange structure to install the flywheel.

The main journal and the connecting rod journal are the most critical sliding fittings in the engine. Generally, they are surface hardened. The transition fillet of the journal must be processed by rolling strengthening and equalization to improve its Anti-fatigue strength.

The axial positioning of the crankshaft generally adopts thrust plates or flanged bushes, and the positioning device is installed at the first main bearing at the front end or at a certain bearing in the middle.

Crankshafts are generally forged or casted with high-quality medium-carbon structural steel, high-quality medium-carbon alloy steel or high-strength ductile iron with high strength, impact resistance and wear resistance.

The crankshaft must undergo a dynamic balance check before assembly. For an unbalanced crankshaft, a part of the mass is often drilled on the heavier side of the balance weight or crank to achieve the balance requirement.

Flywheel

The flywheel is a disk with a large moment of inertia. A ring gear is pressed on the outer edge, which meshes with the drive gear of the starter and is used when the engine is started.

The flywheel is usually marked with the ignition timing of the first cylinder to calibrate the ignition timing.

The flywheel of a multi-cylinder engine should undergo a dynamic balance test together with the crankshaft. In order to ensure that the assembly relationship between the flywheel and the crankshaft is not damaged during the disassembly and assembly process, the positioning pin or asymmetric bolt arrangement is adopted, and attention should be paid during installation.